Restoration of HNW610K

A look at the Restoration of my own DBS V8.I spent 3 years looking for a DBSV8 looking from Scotland to Kent.

After viewing 8 different cars I finally found the right car although it took a further 12 months to actually own it.

But that's another story.

This is the day my DBS V8 arrived.

Here are some pictures before I started

As can be seen it was a bit of a Hot Rod.

It Begins.

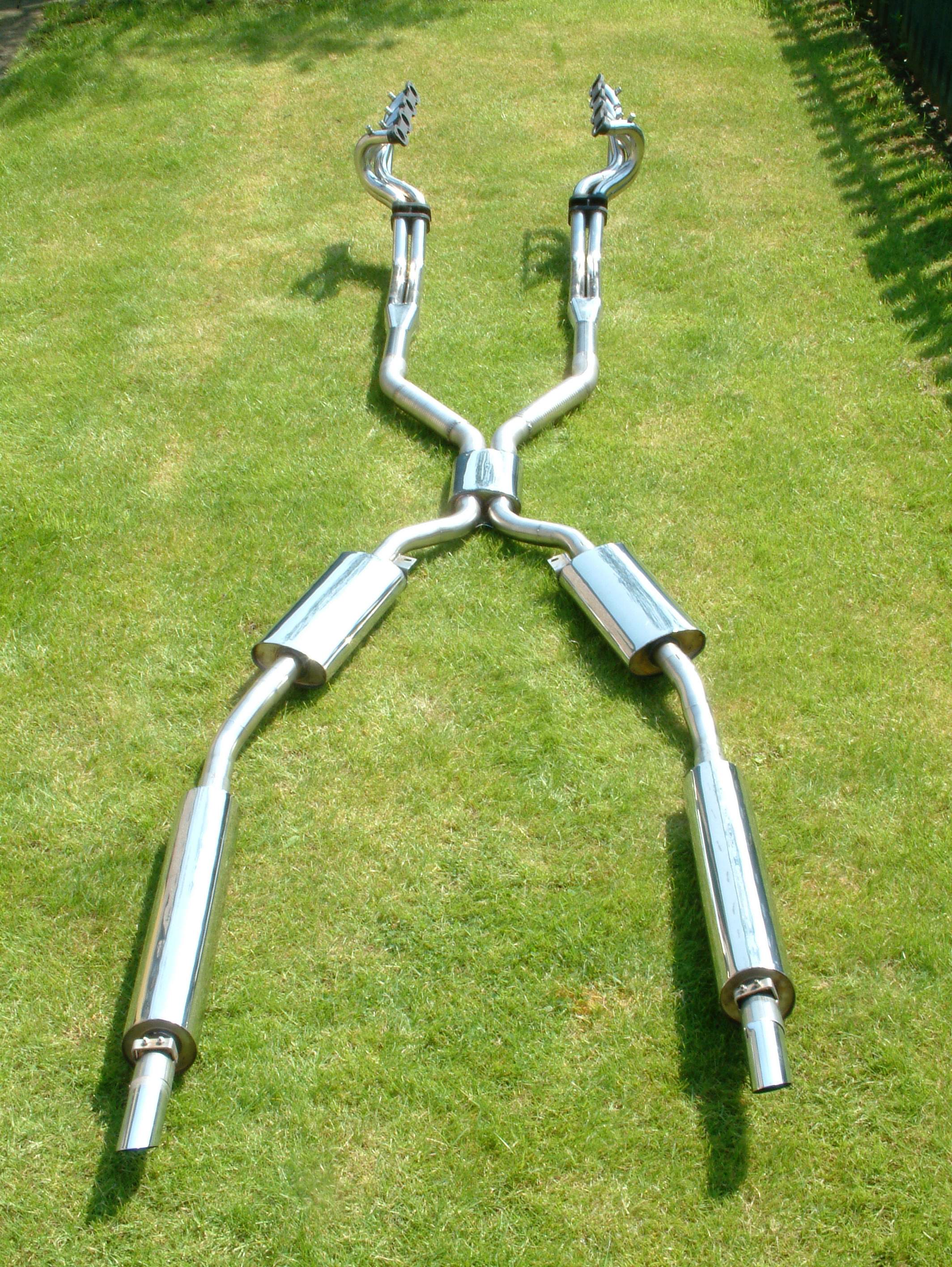

As I had spent a long time researching and looking for the right car, I wanted to have the nicest original looking DBSV8 so I decided on a sympathetic restoration using as many of the original parts as possible.

Bumpers first

I decided that the first thing to do was fit some bumpers as the originals had been stolen before I purchased the car. Luckily the original brackets were still with the car so I used them as patterns and made some replacements in Stainless steel.

Door Mirrors

Mirrors next, after a bit of research I found that the car shared mirrors with a few different Mercedes models from the 1960's

Door Mirrors

Luckily I found a Mercedes parts man on line in Germany who could source OEM ones for a third of the price of the UK

Wheels and Tyres.

When I purchased the car I was told the original wheels were with the car.I did not see these on the 2 visits I had before I eventually got the car it wasn't until I picked it up that I was shown some very scruffy but original wheels stored in plastic bags.

Wheel restoration

I stripped the wheels by hand and then found a company that could re-machine the rims. So first I got them powder coated the original silver then they were lightly diamond turned to bring the surface back.

I then took them home and hand polished all five wheels going from 400 grit to 2000/8000 grit before autosol to get a mirror finish on the alloy. (tip: don't do all five at once take a break as it less painful on the fingers)

I then had to source some tyres, this is quite difficult as there are only a couple of manufacturers who still do this size of tyre* so I opted for the Avon tyres as recommended. Unfortunately the original wheels don't have a machined centre so they have to be balanced with a machine that picks up off the studs. Luckily I have now located a local independent tyre fitter that does this quite reasonably.

*GR70V or 225-70/15VR

Looking more like an Aston

So after wrestling with a new set of bumpers, mirrors, number plates and a good polish and wax the car was looking more like it should do.Time to sort out the rich running.

Valve clearences

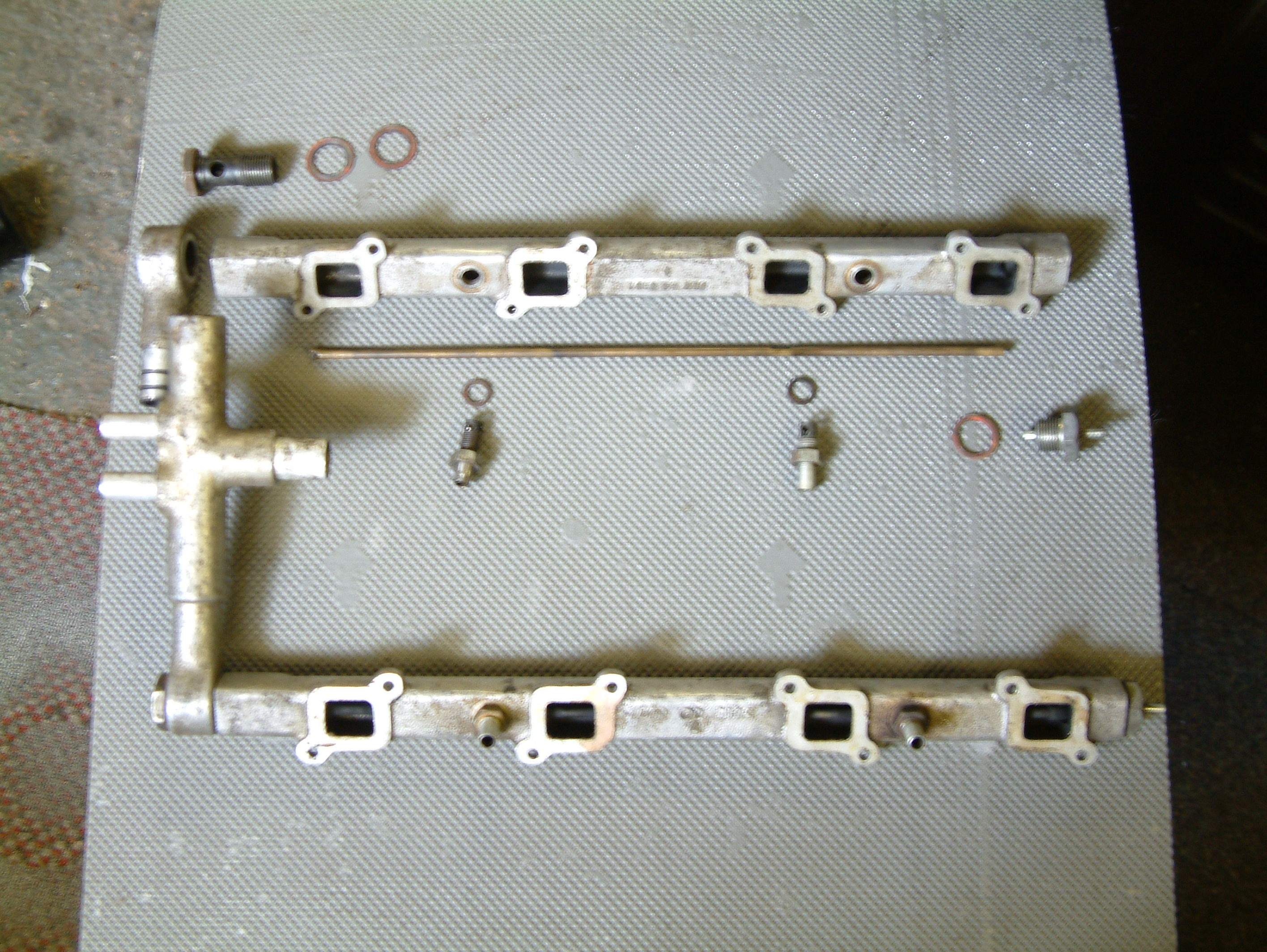

So it says the first thing to do before anything else is to check the valve clearences. Easier said than done as most of the engine has to be removed first

A Bank

We are very luck today as we have digital cameras so all parts removed has a photo and I kept a book with all values and everything was tagged and bagged.

Engine bay

After removal of most of the top of the engine it was quite easy to see the condition of the engine bay so I thought I can't just get the engine running right I had to tidy this first.

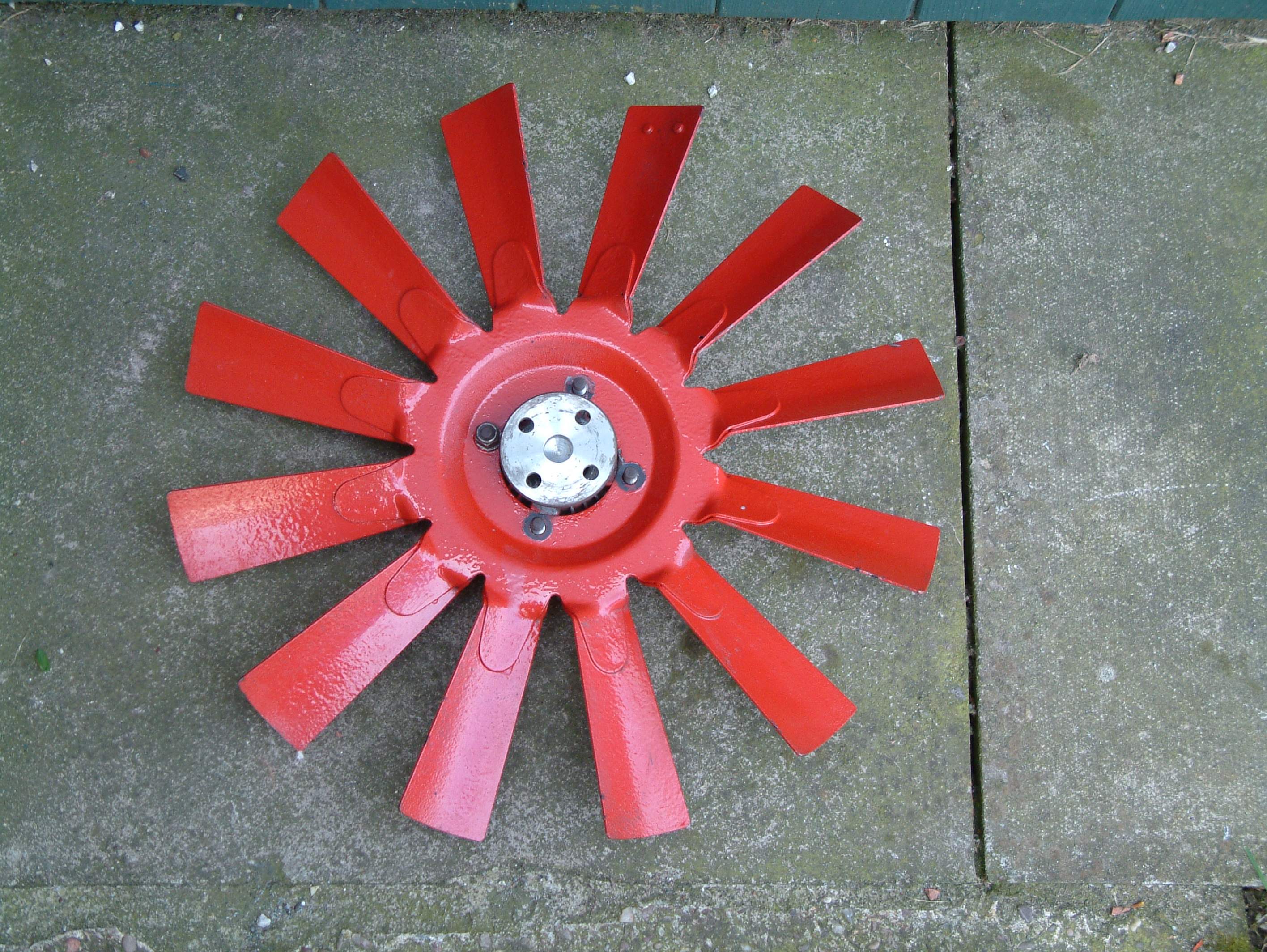

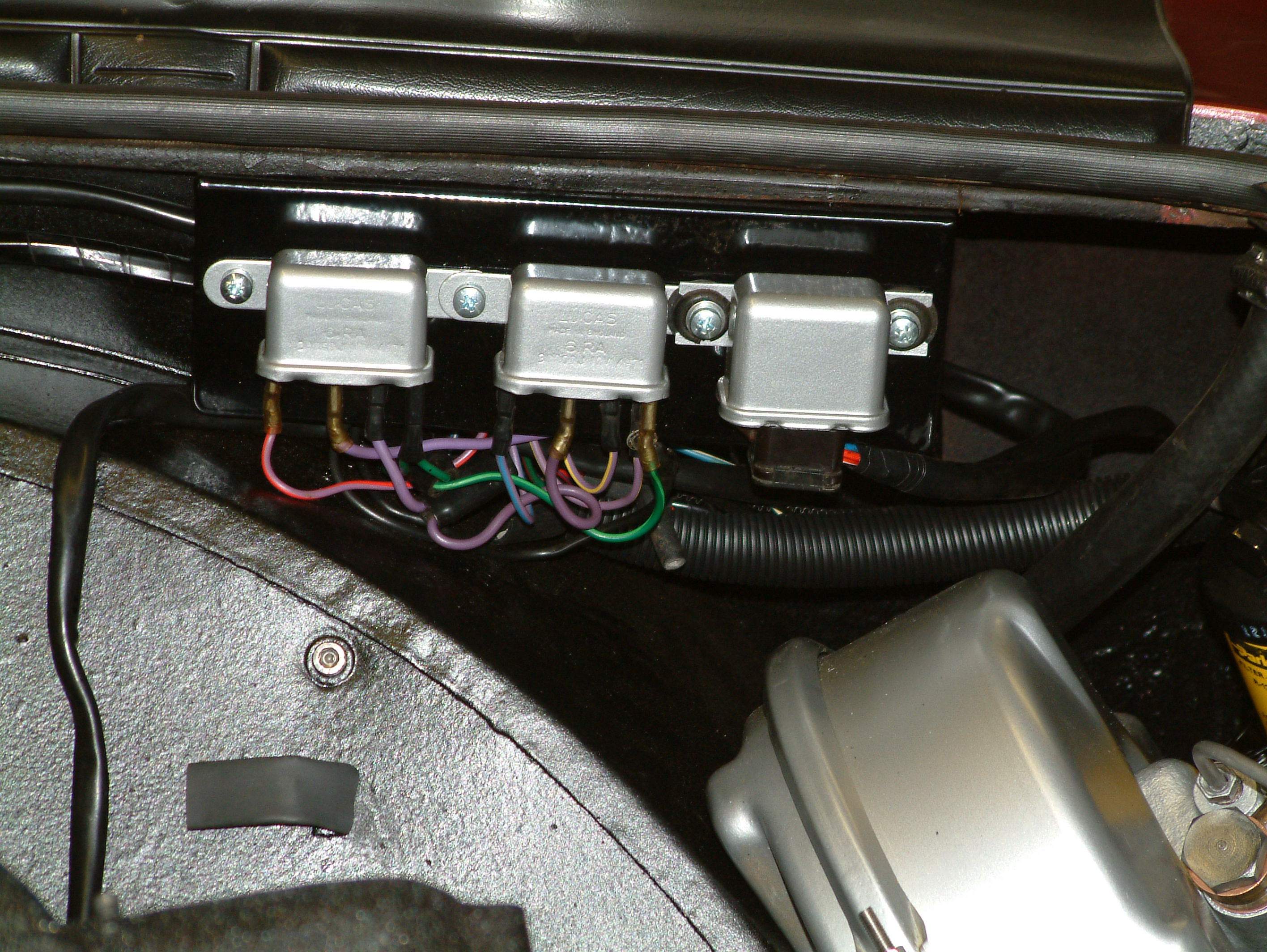

A start.

Here are just a very small selection taken during the engine bay tidy up. Apart from perished pipes and damaged clips most parts were refurbished and put back to keep it original. I do break some rules as I am addicted to stainless fasteners and fittings, so where possible these are used to prolong the life of the car. I also powder coat where possible for the same reason.

TO BE CONTINUED.......